Filtronetics, Inc, is a pioneer in the development and manufacture of RF Products. Our design expertise makes us the number one choice of global defense and telecommunications industries.

Filtronetics has 5 decades of experience in the RF Industry. Experience that transforms your design obstacles into our solutions. We employ a technical/engineering staff with an average of 20+ years experience per person. Their range of expertise includes Electrical Engineering, Mechanical Engineering, Auto-Cad, Hi-Reliability Design & Assembly, PC Board Layout, Test & Verification and Specialized Troubleshooting.

Filtronetics has designed and produced thousands of high reliability filters used in United States space, defense and flight programs. We have an unrivaled Space Heritage and maintain status as a DLA certified and NASA approved vendor.

Design and Test

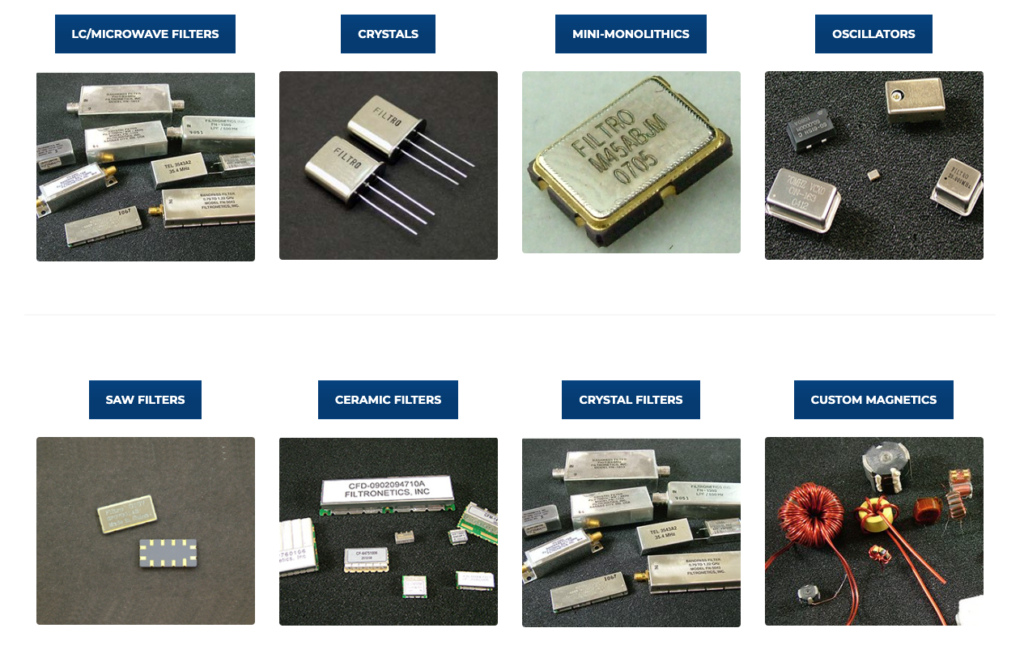

FILTRONETICS, Inc. offers extensive design experience and capabilities. We provide custom designs for filters, oscillators, crystals, custom magnetics, electronic systems, and electro-mechanical assemblies. We have experienced engineers, scientists, and draftsmen who complete projects in a cost-effective, professional manner. We routinely provide documentation such as simulations, drawings, and test results. We build from prototype up to production runs.

Many of the following tests are performed at Filtronetics’ facility. Others are performed at approved certified laboratories that specialize in these tests. Testing and quality inspection can be performed to specific standards such as:

MIL-STD-202, MIL-F-18327, MIL-STD-883, MIL-STD-810, MIL-STD-220, MIL-STD-210, and IPC/J-STD

Assembly & Packaging

FILTRONETICS, Inc. uses our extensive knowledge and experience to aid in the design, manufacturing and testing of both electrical and mechanical assemblies.

Some of our assembly capabilities:

- Complete System Assembly and Testing

- Sub-Assembly & Printed Circuit Board Assembly

- Hand & Automated SMT Assembly

- Coil Winding / Custom Magnetics

- Crystal Manufacturing

- Custom SMT and Thru Hole Packaging

- Temperature Testing

- Shock and Vibration Testing

- Voltage Burn-In

- Encapsulation / Foaming

- Modification or upgrade to an existing product

Filtronetics, Inc. uses our extensive experience to customize packaging allowing components to work in harsh environments and withstand the rigors of automated assembly.